A collaborative research team led by Professor Zhang Li has developed an innovative inverse programming technology for magnetic soft materials. This technology allows for precise programming of the magnetisation distribution, enabling the material to be controllably transformed into the desired three-dimensional surface according to specific requirements under magnetic actuation. This breakthrough opens new application possibilities in many fields, including information storage, biomimetic soft robots and precision medical technology. The research results have been published in the internationally renowned journal Nature Synthesis.

New technology overcomes challenges in inverse programming of magnetic soft materials

Inspired by nature, the research team observed how the soft tissues of living organisms dynamically present 3D curved surfaces, a capability that plays a critical role in vital physical processes and the maintenance of health. For example, human skin and muscles can change shape according to the environment and as a result of movement. However, the complexity of magnetic interactions and the computational demands have made such materials challenging to design and fabricate. Traditionally, simulating and designing magnetic soft material modules has been a highly challenging task requiring significant time and resources.

To overcome this technical bottleneck, Professor Zhang and Dr Xia Neng from CUHK, along with Professors Jin Dongdong and Ma Xing from Harbin Institute of Technology (Shenzhen), and Professor Wang Liu from the University of Science and Technology of China, collaborated to develop a new strategy. It leverages precise control of the light source to programme magnetic soft materials, enabling dynamical and reversible transformations into 3D surfaces under magnetic actuation.

The team first prepared a hydrogel material infused with magnetic particles and then developed a photocuring 3D printing method to process these magnetic hydrogels. By precisely adjusting the intensity distribution of the light source during printing, they achieved a heterogeneous magnetic hydrogel, temporarily transforming from its original 2D shape into a 3D surface. By applying a pulsed magnetic field, they magnetised the deformed magnetic soft material, creating a 3D magnetisation distribution that allows it to present different 3D shapes under the influence of an external magnetic field. Additionally, the team developed a computational method to guide the design of the light source, ensuring that the printed magnetic soft material accurately reproduces the target 3D surface under magnetic actuation. This innovative strategy significantly reduces the complexity and improves the precision and efficiency of programming magnetic soft materials.

For the full research, please visit: https://www.nature.com/articles/s44160-025-00746-2

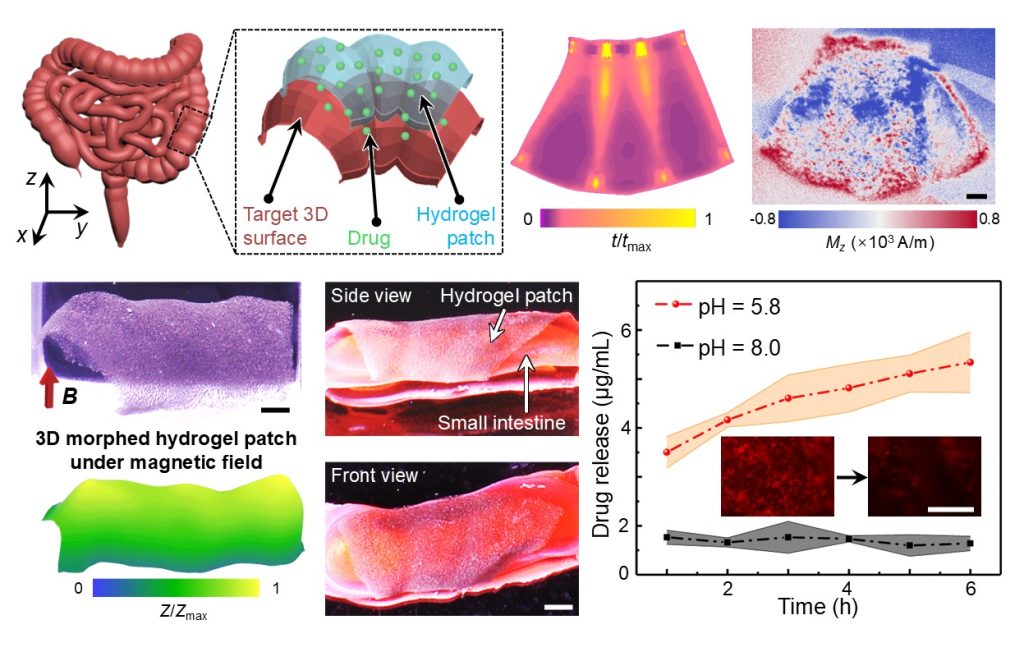

Through inverse programming of magnetic soft materials, personalised medical patches can be constructed according to the structure of the patient’s digestive tract, enhancing the efficiency of precision treatment.

The programming of magnetic soft materials utilises 3D printing technology to create programmable magnetic soft materials (Figure 3a). The inverse design method for the magnetisation distribution of magnetic soft materials (Figure 3b).

Magnetic soft materials constructed based on inverse design can accurately form specified 3D curved surfaces under the influence of magnetic fields.

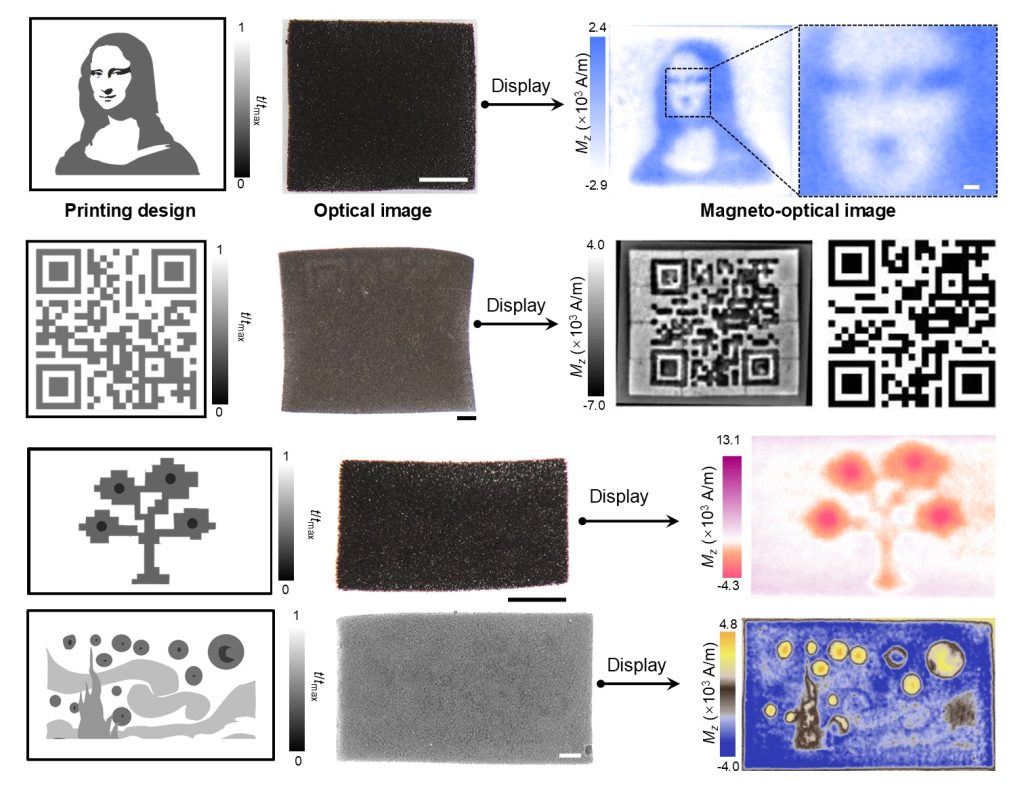

Programming of the magnetisation profiles encodes the information of Da Vinci’s Mona Lisa, a QR code, a fruit tree pattern, and Van Gogh’s The Starry Night in magnetic soft materials.

CUHK Press Release: Click here!