Several MAE students and their supervisors have received a total of four awards under the Innovation category and the Entrepreneurship category at the 6th Hong Kong University Student Innovation and Entrepreneurship Competition 2020 held on May 29 this year, including one First-class Award, two Third-class Awards and one Merit Award. The excellent result shows that MAE students not only are innovative but also have entrepreneurial potential. A big applause for them!

Category: Entrepreneurship

First-class Award: LaSense Ultra-sensitive Gas Sensing and Control System by Ke XU and Prof. Wei REN

PhD student Ke Xu and Prof. Wei Ren established a startup named LaSense Technology in November 2019, and have designed and developed a set of ultra-sensitive gas sensing and control system aiming at the urgent market demand from energy industry. The developed distributed on-line monitoring system based on laser spectroscopy will be used in the denitration process control to improve the denitration capacity and efficiency of the power plant, and to achieve the source prevention of air pollution as well. This invention also combines multiple technologies including self-developed automatic feedback control, artificial intelligence algorithm, advanced chip integration, wireless data transmission and rapid signal processing.

Site visit to a coal-fired power plant in Guangdong Province.

First-generation LaSense ultra-sensitive gas sensor.

Team photo: Prof. Wei Ren (left) and Ke Xu (right)

Category: Innovation

1) Third-class Award: Annealing of Strontium Titanate Based Thermoelectric Materials by Graphite Mechanistic Analysis by Spectroscopic and Chromatographic Techniques by Haoran LI (Supervisor: Prof. Yongsheng CHEN)

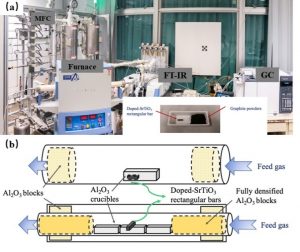

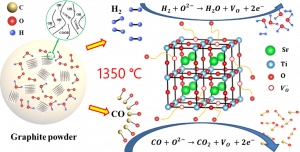

PhD student Haoran Li has successfully revealed the annealing mechanism of SrTiO3 based ceramics using graphite. It is not through carbothermal reduction but through the reducing agents, H2 and CO, which are generated from graphite in the annealing process. Additional CO is produced in carbon incomplete combustion. This mechanistic study suggests that more reducing agents can be used in the annealing process, and the process can be controlled by manipulating the chemical environment assisted by analytical techniques. Wide application of this approach has the potential to turn the current ceramic annealing technique into a science.

(a) Picture of the integrated annealing system for SLTB/20Ti samples with graphite powder in an atmosphere-controlled and monitored tubular furnace. (b) illustrations inside the furnace tube for annealing with graphite powder (upper) and a modified setup with a much smaller internal volume for annealing with CO (lower).

Illustration of the mechanism in the annealing of SrTiO3– based materials by graphite.

2) Third-class Award: Modularized ROV by Chun Keung KWOK (Supervisor: Prof. Darwin LAU)

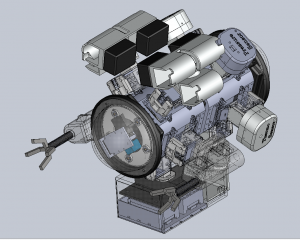

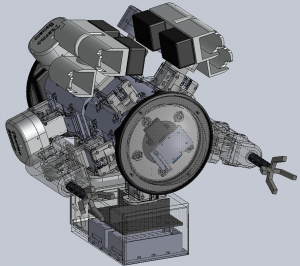

The Modularized ROV is an underwater robot which ensure underwater engineering tasks safer and easier than ever. It is a universal underwater manual robot that is adoptable to a series of interchangeable end-effectors, i.e. actuators and sensors. To tackle the varied challenges underwater, users can assemble a unique ROV by choosing the suitable modules for their specific tasks. The concept of Modularization is remarkably adopted in the structural design. Even the batteries, cameras and thrusters are modularized and capable for replacement and upgrade.

Modularized ROV CAD

ROV CAD1

ROV CAD2

ROV Real Model

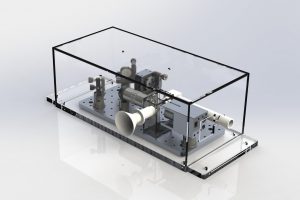

3) Merit Award: Portable Microscope System for Real-Time Aerosol Measurement by Songyun GU, Bingxu CHEN (Supervisor: Prof. Shih-Chi CHEN) and Huasheng LAI (Surgery Dept.)

Real-time aerosol measurement (RAM) system is a high-speed microscope which is specially optimized for aerosol detection. It can simultaneously measure essential information of the flowing aerosol, such as velocity, flow rate, concentration, and size distribution. To evaluate the danger of infection for doctors, RAM system is applied in simulated endoscopic surgery to detect the aerosol generated by patients.

CAD Model of RAM System

RAM System in Operation